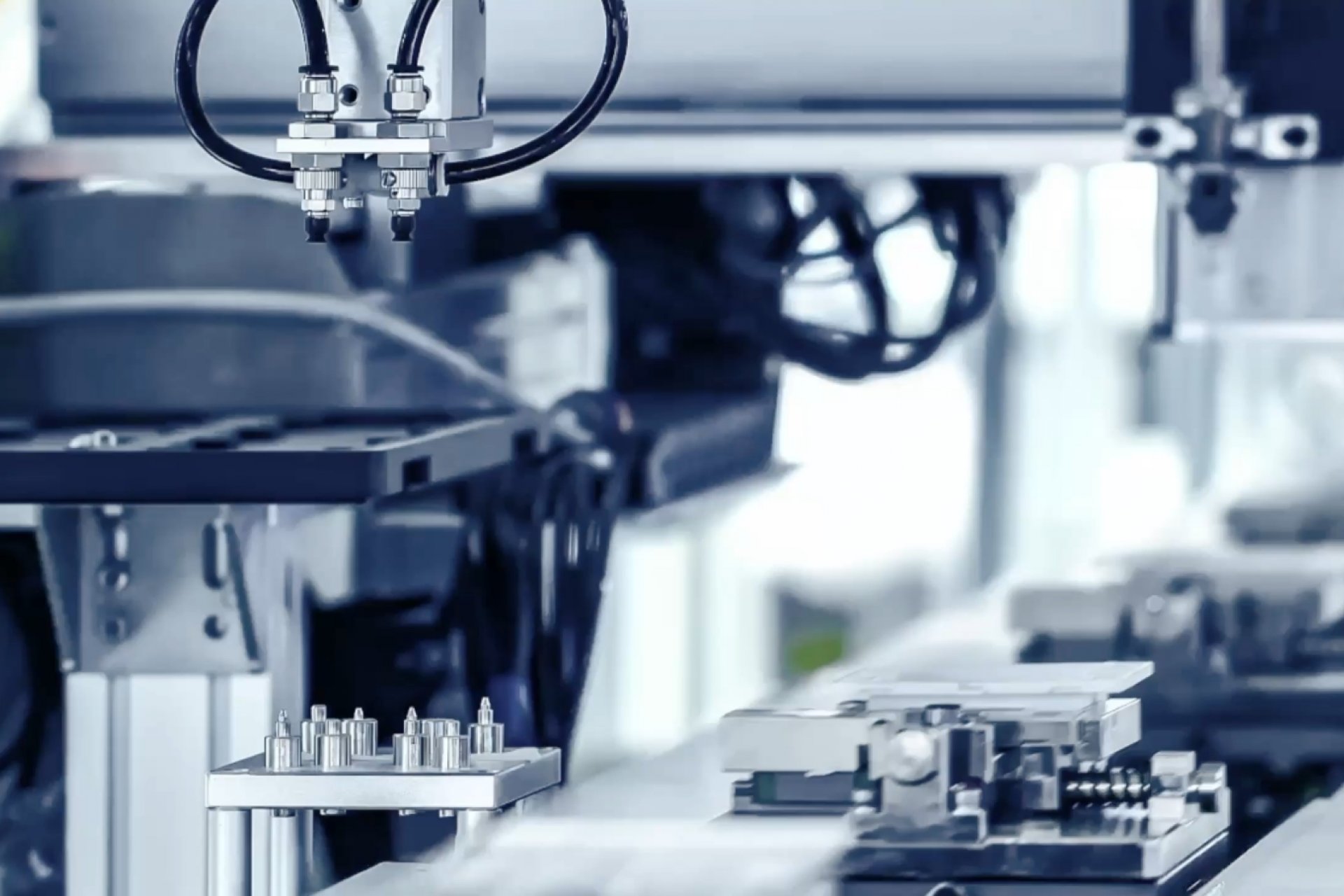

Automation solutions

Modular and customized solutions

to meet your individual requirements.

Tailored automation, 360° worldwide support.

Our standalone systems and seamlessly integrated solutions are engineered to propel your molding process into the future. Embrace unparalleled flexibility with our modular approach, designed to adapt and grow with your needs. Whether upgrading current lines or developing new projects, Vasantha’s automation solutions ensure efficiency, precision, and scalability. Transform your plastics-manufacturing landscape and enter new levels of productivity.

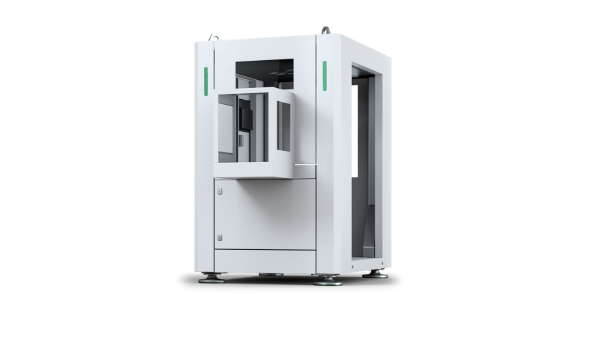

Vusion

Take-out Unit

A versatile solution designed to optimize the post-injection molding process. A robotic arm efficiently removes the product from the injection molding machine, seamlessly transferring it to the production cell. Within the cell, the product undergoes inspection and is precisely sorted into the appropriate categories of good and bad. With its modular design, our take-out unit offers flexibility and adaptability to suit your specific production requirements.

Vusion

Assembly Unit

Our multi-component assembly unit is designed to streamline and optimize your assembly processes, enabling efficient production of complex products.

Vusion

Test and Inspect

Our test and inspection cell has been specifically developed to assess component requirements for functionality as efficiently as possible. This evaluation is facilitated using camera systems and/or various other testing equipment. Furthermore, the stations are designed to connect directly and can be customized to meet each customer's unique requirements, ensuring a highly adaptable and efficient testing environment.

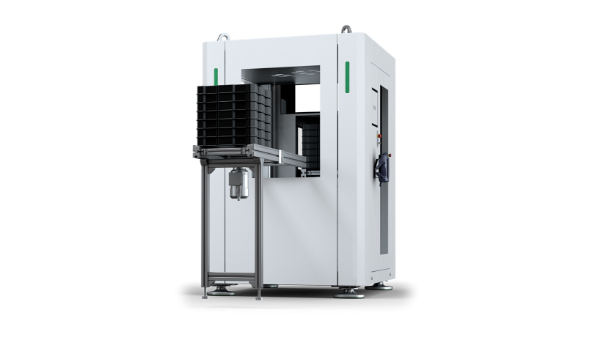

Vusion

Tray Loader

The tray loader is designed to efficiently pack components into customized trays, tailored specifically to the dimensions of length, width, and height. It ensures seamless adaptation to various tray sizes. To maximize operational autonomy, the trays are systematically stacked and unstacked, and then re-stacked on the opposite side once they are filled with components. This process ensures continuous productivity without frequent interruptions.