VTW Austria

Home of high-precision moldmaking

VTW was founded in 2019 by former KTW managers and Vasantha Group.

Together, we draw on over 80 years of experience in high-precision toolmaking, combining concentrated know-how with cutting-edge technology and a high degree of automation.

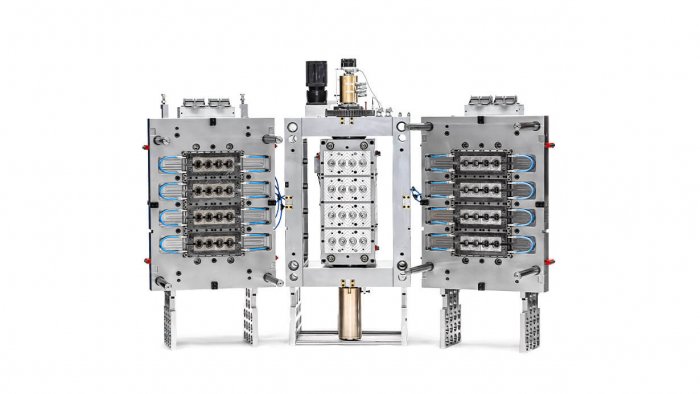

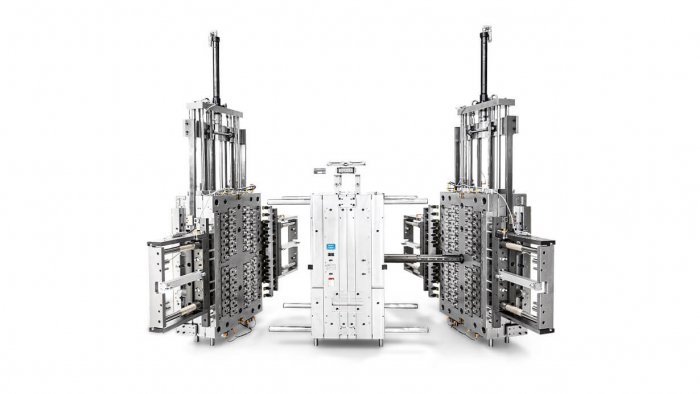

Located in Waidhofen an der Thaya – a region in Austria internationally recognized for its excellence in toolmaking – VTW employs more than 70 full-time professionals. We have the capacity to build more than 50 high-cavitation molds per year and operate a state-of-the-art 4000 sqm facility including tool room, testing laboratories, office, and customer areas.

Our production environment is fully climate-controlled, highly automated, and certified according to ISO 9001:2015. This ensures the consistent fulfillment of customer requirements, increased efficiency, and standardized processes throughout the entire operation.

VTW features fully automated robotic manufacturing lines with 5-axis milling and EDM technology. We rely on equipment from industry-leading brands such as Röders, Yasda, ZK, Studer, Arburg, Fanuc, Hembrug and Engel.

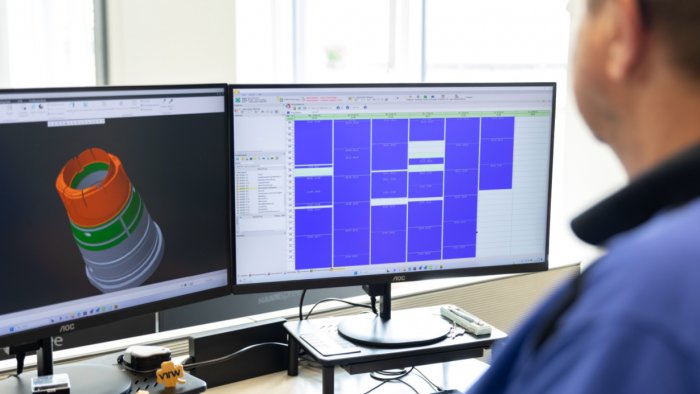

From product idea to ready-for-production mold, we offer a complete in-house solution – including concept studies, product design, mold design, reverse engineering, and CAD data preparation. Our mold development process integrates advanced simulation technologies such as mold flow and cooling analysis to ensure optimal performance and manufacturability.

- Global Footprint – Local support in Asia, Europe and US

- New world class facility for 100% repeatability of product dimensions and quality

- IoT capable working cells supporting real-time capacity planning

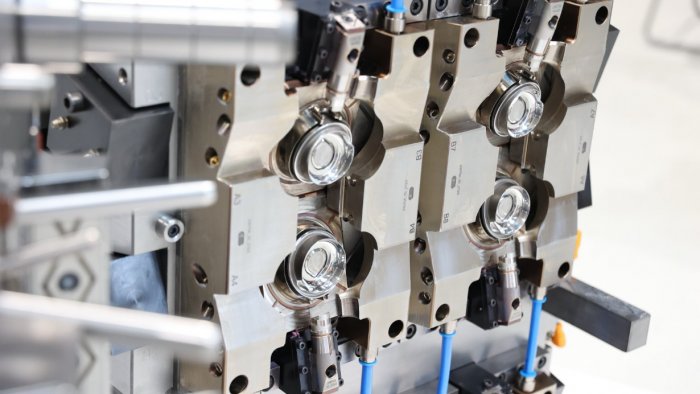

- Extensive experience with conformal cooling for best part quality & cycling time

- Hybrid cavity inserts

- Sandwich inserts / vacuum brazing

- Direct metal laser sintering

- Long-running and proven cavity stack design to minimize total cost of ownership

Industrial Product

Design Support

Sustainable

Packaging

- Efficient lightweight solutions

- Resin harmonization (e.g. closure & bottle) to simplify recycling processes

- Compostable materials, e.g. PLA resin

Consumer

Convenience

- Flexible packaging

- Re-useable & Re-fill solutions

- Haptic design

Tethered

Closures

- Technical support to the development partner to achieve the product specification and performance

Innovations

& Developments

Conformal

Cooling

- Direct Metal Laser Sintering with application specific materials

- Sandwich inserts / vacuum brazing

- Hybrid cavity inserts & cores

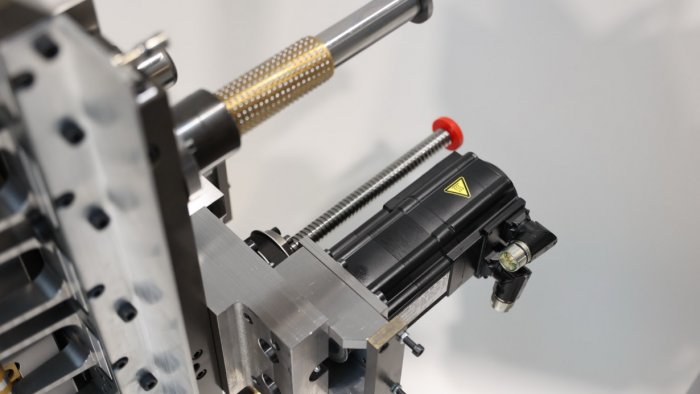

Mold

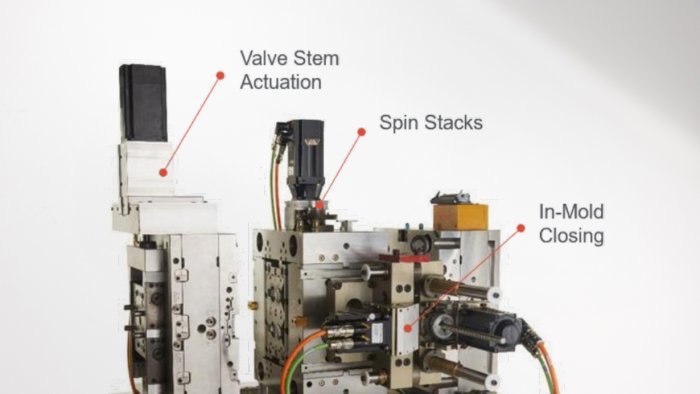

Electrification

- Plug & play system - Injection moulding machine independent

- Dual-axis Servo IMC with flexible & user-friendly servo drive controller

Mold Condition Monitoring

– cooperation with SAVYA

- Mold Alignment Sensoric

- Sensorics based on structure-borne sound technology

Equipment

VTW stands for cutting-edge manufacturing technology at the highest level. A climate-controlled working environment and best-in-class high-performance equipment ensure precise and stable production conditions. Our IoT-compatible working cells enable seamless integration into digital processes. Fully automated robotic lines for EDM and 5-axis milling provide maximum process automation and repeatability. This is further enhanced by real-time workload planning and capacity simulation, ensuring efficient resource utilization and consistently high production quality.

- 24/7-manufacturing

- Intelligent job-management

Organisation of work orders through communication between the machines. No downtimes due to waiting for the individual stations

State-of-the-Art

Technical Center

Precision, performance, and validation excellence – all under one roof at the VTW Technical Center.

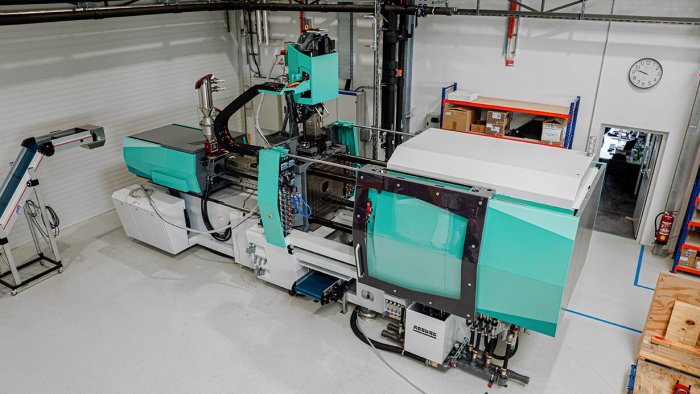

The VTW State-of-the-Art Technical Center is equipped to handle a wide range of requirements with injection moulding machines from 1500 kN to 6500 kN, and dedicated bays for seamless customer system integration.

Advanced validation methods using Design of Experiments (DOE) combined with fully adjustable cooling parameters ensure consistent conditions — both during internal testing and at the customer’s site.

To guarantee precision and quality, the Technical Center offers comprehensive metrology capabilities including coordinate measuring machines (CMM) with both optical and tactile sensors, 3D scanning, and high-resolution computer tomography (CT).

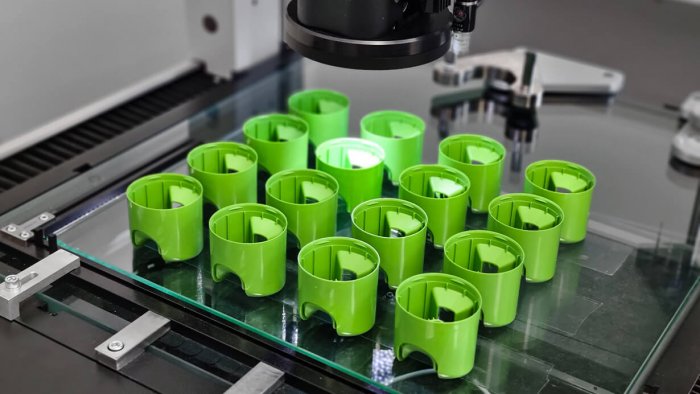

Product

range

Our

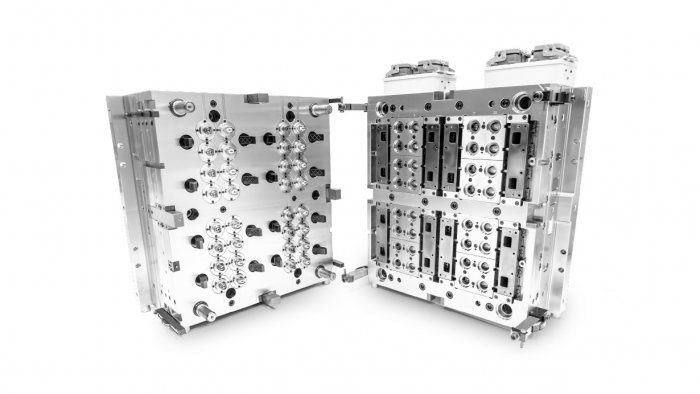

Molds

Get to know our state-of-the-art tool room with climate-neutral working environment that has world-class high-performance equipment, IoT suitable working cells, fully automated robotic lines with EDM machines & 5-axis milling machines. All are supported by real-time workload planning & capacity simulation software.

48.81583, 15.2737

Get in Touch

Contact VTW by e-mail or phone.

3830 Waidhofen/Th., Austria