3D Mold Design Bring Your Imaginary

Concept to Life with Vasantha

Conceptual Sketch

The journey begins with a simple sketch—your conceptual idea taking shape on paper. Vasantha understands the importance of this initial phase, where creativity meets practicality. Our team collaborates closely with clients to refine and enhance these sketches, laying the groundwork for a successful mold design process.

3D CAD Software

Choosing the right tools is paramount in achieving exceptional results. At Vasantha, we rely on 3D CAD software for its advanced capabilities and seamless integration. This software empowers our designers to bring your designs to life in a virtual environment, ensuring accuracy and efficiency throughout the process.

Generating 3D Design

With the software at our disposal, our skilled designers begin the intricate task of generating the 3D design of the mold. Every curve, angle, and detail is meticulously crafted to perfection, ensuring that the final product meets and exceeds your expectations.

Study Mold Mechanism & Simulation

A crucial step in the mold design journey is the study of mold mechanism and simulation. Vasantha's team conducts thorough analyses and simulations to identify potential challenges, optimize the design for efficiency, and ensure seamless functionality in real-world applications.

Releasing Drawing for Manufacturing

Once the design is finalized and approved, detailed drawings are released for manufacturing. These drawings serve as a blueprint for our production team, guiding them through the assembly process and ensuring that every component aligns with the design specifications.

Assemble All Manufacturing Parts

The assembly phase is where the magic truly happens. Our skilled technicians meticulously assemble all manufacturing parts, paying attention to the smallest details to guarantee a flawless end product. Each component is carefully integrated to ensure optimal performance and longevity.

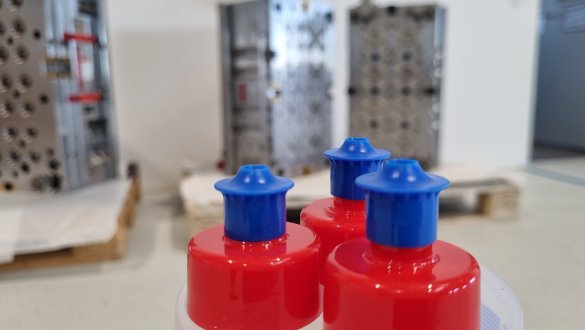

Mold Ready for Trial

After rigorous quality checks and final inspections, the mold is deemed ready for trial. This pivotal stage allows us to test the mold's functionality in real-world conditions, make any necessary adjustments, and fine-tune the design for optimal performance.

Conclusion

In conclusion, Vasantha's commitment to excellence, innovation, and sustainability shines through in every mold design project we undertake. By bringing your imaginary concepts to life with precision, expertise, and a focus on sustainable packaging solutions, Vasantha paves the way for a brighter, more efficient future in the world of injection mold design.

Partner with Vasantha for all your mold design and injection molding needs, and experience the difference that expertise and dedication can make in turning your ideas into reality.

Authors: Gandham Rajini Kumar & Paul Rithwik