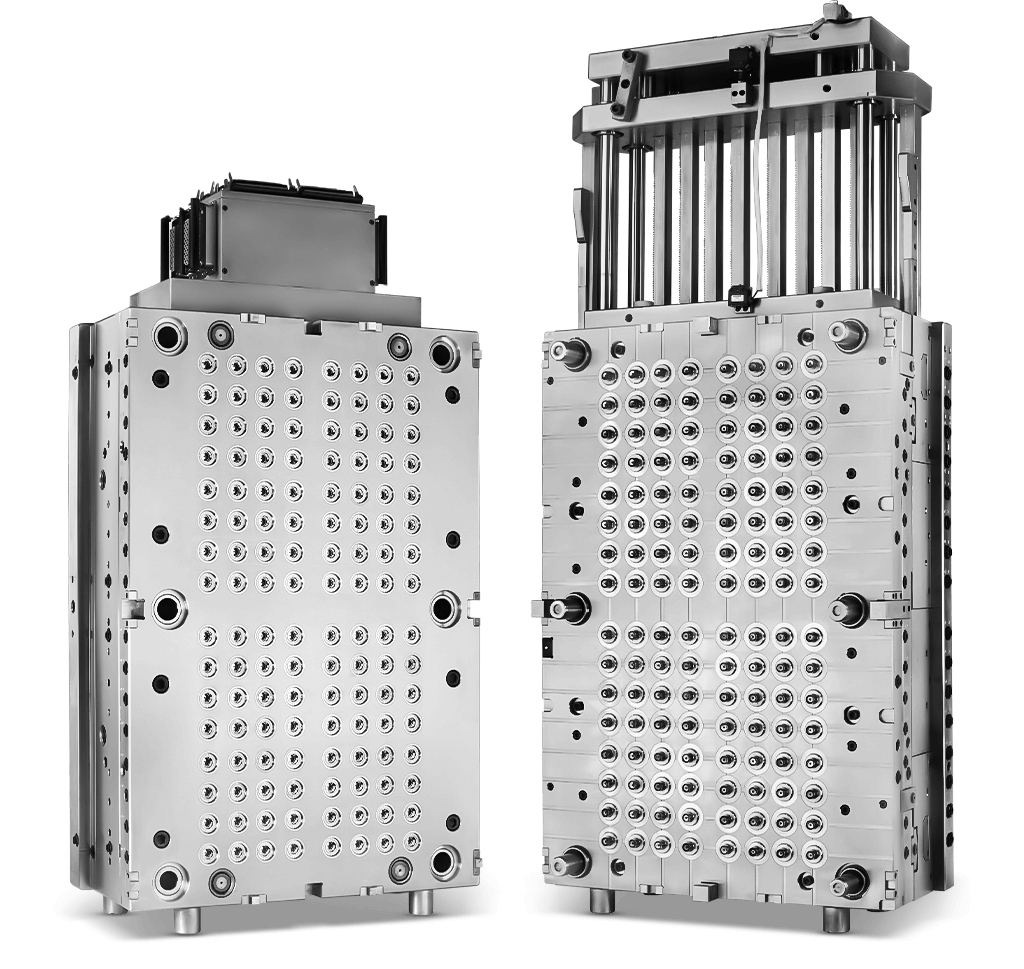

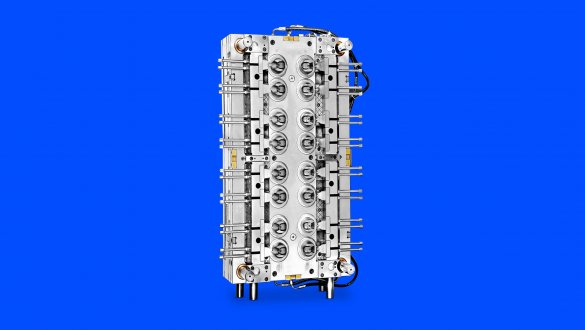

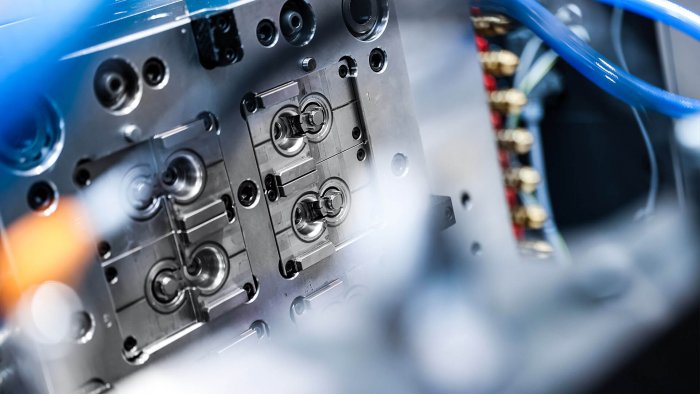

Injection Molds

100% Built In-House

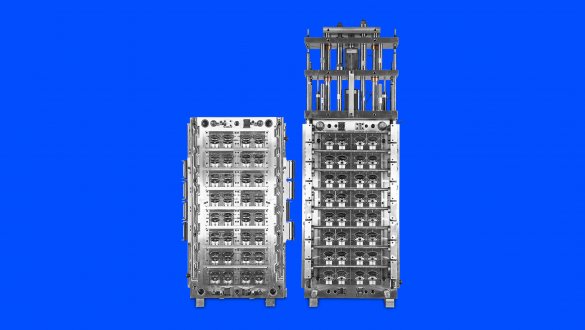

Today Vasantha builds injection molds across three continents. All stacks are 100% built in-house.

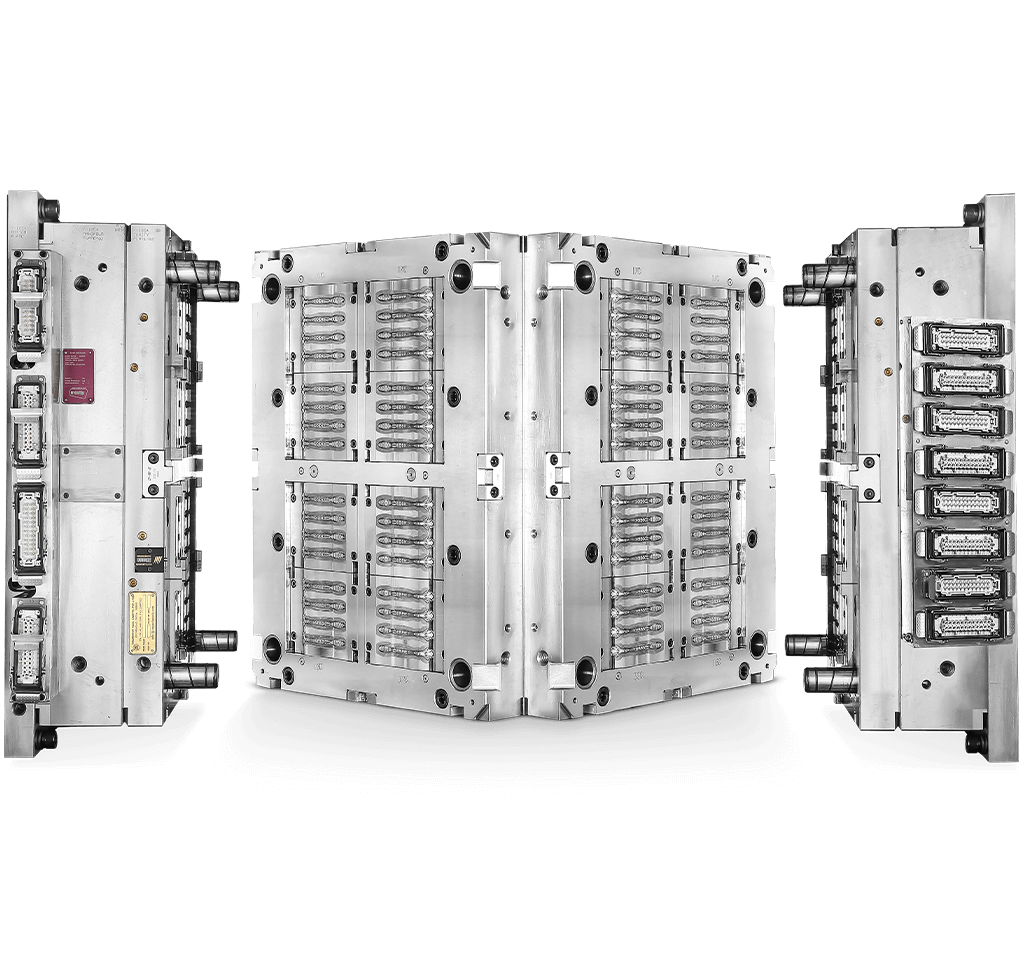

In India and Austria, we build high-cavitation multi-cavity molds for global customers. What is common across all two locations is our commitment to the customer on quality, delivery and service. No matter where the molds are built, they can be validated at any location worldwide.

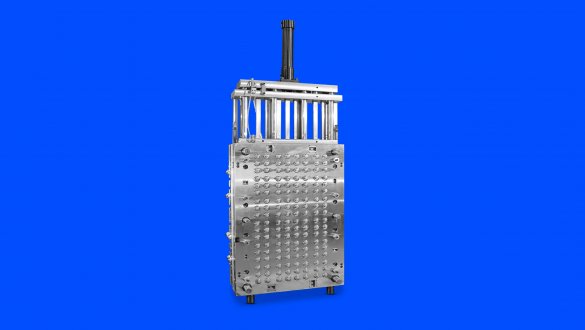

Interchangeability

Fast lead times

Innovative and economic

High capacity

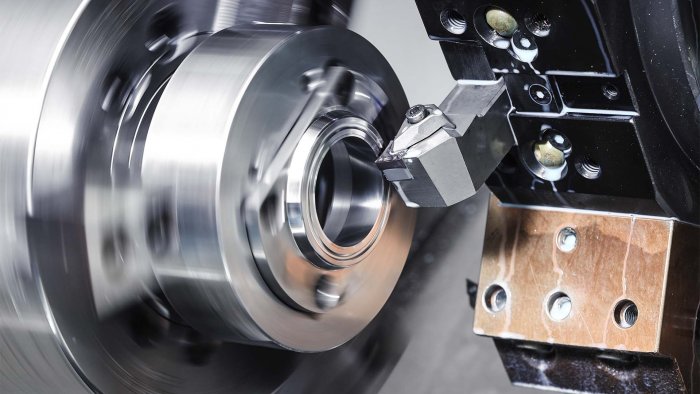

Mold-making

is in our DNA.

Vasantha started making high-complex molds in 1989. Today, after more than three decades, our love for mold-making has only increased. Since our inception, we have experienced steady organic growth, averaging an impressive 15% annually.

We began as a specialty mold-maker focused on switch gear and white goods components, but our journey led us to recognize the immense opportunities in high-volume FMCG and medical segments. For more than three decades, these sectors have been our primary focus, driving continuous innovation at every step.

Many of our global customers trust us as a reliable partner for their extensive programs that involve multiple molds across various locations. We are well-equipped to handle such projects seamlessly. Presently, our molds are operational in nearly 50 countries worldwide, showcasing both customer loyalty to Vasantha and our ability to collaborate with diverse cultures across the globe.

Experience

Quality

Global Service

Vasantha Group is a world class and a global supplier of high-volume tooling

offered at an unbeatable combination of quality, price and delivery.

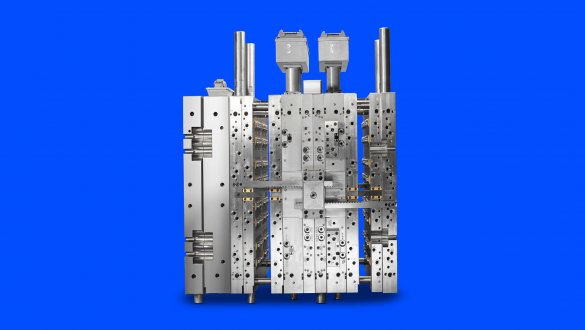

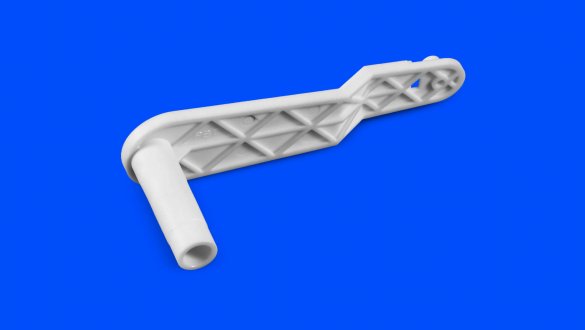

Application

Examples

Our diverse portfolio includes molds for packaging, medical and many other special applications.

Our Mold-Making

Companies:

Vasantha Tool Crafts

VTC has a capacity to build 400 high-volume molds per year in less than 12 weeks, for packaging and medical markets.

VTW

With about 30+ years of experience, VTW has the ability to build the most complex tools in the industry at very competitive prices and lead time.

Savya Automation

Savya Automation delivers high-tech automation solutions and complete project execution with a strong R&D team in India and Austria.